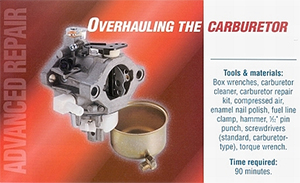

How To Repair A Briggs And Stratton Carburetor

How do you rebuild or overhaul a pocket-sized engine carburetor?

Rebuilding the carburetor may be required if basic adjustments don't gear up your small engine problems or better performance on your backyard mower or outdoor power equipment. Follow the steps beneath for overhauling pocket-size engine carburetors.

![]() WARNING: E'er read the engine and equipment manual(s) before starting, operating, or servicing your engine or equipment to avoid personal injury or property impairment. Fuel and its vapors are extremely flammable and explosive. Always handle fuel with extreme care.

WARNING: E'er read the engine and equipment manual(s) before starting, operating, or servicing your engine or equipment to avoid personal injury or property impairment. Fuel and its vapors are extremely flammable and explosive. Always handle fuel with extreme care.

Come across an authorized dealer or contact Briggs & Stratton if you are unsure of any procedure or have boosted questions. Find all Engine Safety Warnings

Step 1: Removing the Carburetor

Step ii: Disassembling A Float-Type Carburetor

Step 3: Inspecting the Carburetor

Footstep 4: Inspecting Air-Fuel Mixture Screws

Footstep 5: Reassembling the Small Engine Carburetor

Step 6: Attaching The Carburetor & Air Cleaner Associates

Pace 1: Removing the Carburetor

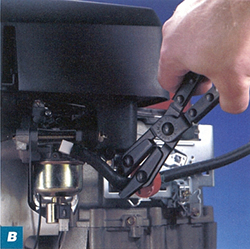

- Disconnect the spark plug lead and secure it away from the spark plug. And then, remove the air cleaner assembly.

- Plough off the fuel valve at the base of the fuel tank. If your engine does not contain a fuel valve, utilise a fuel line clamp to foreclose fuel from draining out of the tank while the carburetor is disconnected from the engine.

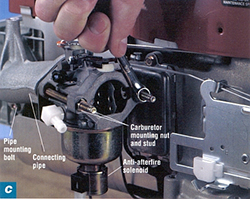

- Some carburetors contain an electrical device at the base of operations of the fuel bowl to command afterfire. Disconnect the device, known every bit an anti-afterfire solenoid, past removing the wire connector from the solenoid's receptacle.

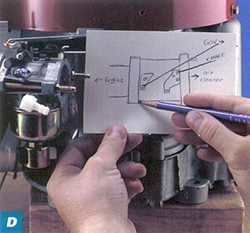

- With the carburetor nonetheless connected to the governor, unfasten the carburetor mounting bolts. If a connecting pipe joins the carburetor to the engine block, starting time remove the pipe mounting bolts. Then, disconnect the carburetor from the pipe by removing the nuts and sliding the carburetor off the studs. Sketch the governor spring positions before disconnecting them to simplify reattachment.

- And then, disconnect the governor springs and remove the carburetor, taking special intendance not to bend or stretch links, springs or control levers.

Step 2: Disassembling A Bladder-Type Carburetor

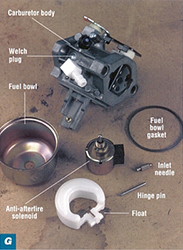

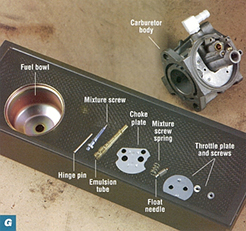

Your carburetor contains a small amount of fuel. Gear up a make clean bowl to catch dripping fuel and store small parts. During disassembly, inspect the bowl for dirt and debris to decide the condition of your carburetor.

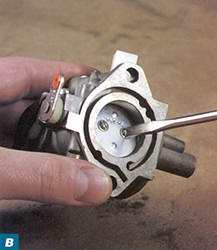

- Remove the fuel bowl from the carburetor torso. The fuel bowl may be attached with either a bolt or the high-speed mixture screw.

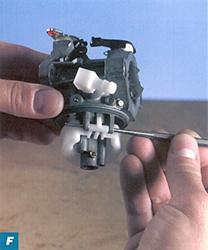

- Push the hinge pin out of the carburetor body with a small-scale pin or pin punch. Take intendance to tap just the pin to avoid damaging the carburetor body.

- Remove the float assembly, inlet needle valve and fuel bowl gasket.

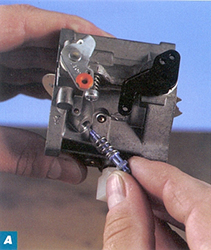

- If your carburetor contains an idle mixture screw, remove it along with the jump.

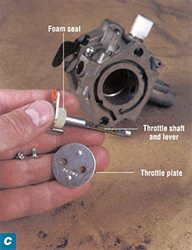

- Rotate the throttle plate to the closed position, remove the throttle plate screws and the throttle plate.

- Remove the throttle plate shaft and cream seal.

- Then, remove the asphyxiate plate and choke shaft and felt or foam washer in the same manner.

- Use your carburetor repair kit to identify replaceable welch plugs. These seals cover openings in the carburetor left over from machining. Insert a sharpened 5/32" pivot punch at the edge of each plug to exist removed and tap cleanly to free the plug.

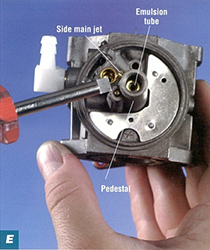

- Unscrew the primary jet from the side of the carburetor pedestal (if equipped). And so, unscrew the emulsion tube; it may exist screwed in tight. A carburetor screwdriver is the best tool for the chore. It'due south designed to fit the slot in the caput or the emulsion tube so that you won't harm the threads inside the pedestal of the tube itself as you loosen it.

- Remove the emulsion tube.

Footstep 3: Inspecting the Carburetor

- Soak metal and plastic carburetor parts in all-purpose parts cleaner for no more 15 minutes to remove grit. Or, while wearing rubber glasses, spray the parts with carburetor cleaner. Then, wipe away solvent and other residue thoroughly using a clean material. Never apply wire or tools because they can harm or further obstruct plugged openings.

- Audit all components and use additional carburetor cleaner to loosen stubborn grit and to articulate obstructions.

- Supplant any parts that are damaged or permanently clogged.

Footstep 4: Inspecting Air-Fuel Mixture Screws

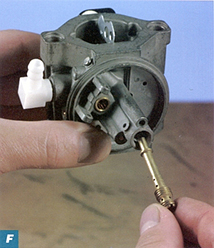

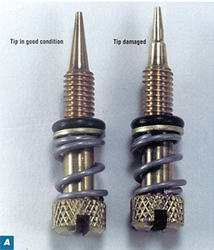

- Brass mixture screws control the air-fuel mixture at high speed and at idle. Over tightening can damage the tip of the screw and then that proper adjustment is no longer possible.

- Remove any not-metal parts and soak mixture screws in carburetor cleaner for fifteen minutes.

- And so, audit them carefully for clothing. Supervene upon a mixture screw if the tip is aptitude or contains a ridge.

Step 5: Reassembling the Small Engine Carburetor

- Install new welch plugs from your repair kit using a pivot punch slightly smaller than the outside diameter of the plug. Tap on the punch with a hammer until the plug is apartment (strong blows with the hammer will cause the plug to cave in). And then, seal the exterior edge of the plug with enamel nail polish.

- Get together the choke by inserting the render spring within the foam seal and sliding the spring and seal assembly onto the asphyxiate shaft. Plastic choke plates have a finish catch at 1 end of the spring; metal plates accept a notch to hold the hook at one stop of the spring.

- Insert the choke shaft into the carburetor body and engage the return spring. If the asphyxiate lever uses a detent jump to command the choke plate position, guide the spring into the notched slot on the choke lever. Place the choke plate on the shaft with the unmarried notch on the edge toward the fuel inlet. Lift the choke shaft and lever upwardly slightly and turn counterclockwise until the stop on the lever clears the bound anchor. Push the shaft downward.

- Insert the choke plate into the choke shaft or attach it with screws then that the dimples face the fuel inlet side of the carburetor. The dimples help hold and marshal the asphyxiate shaft and plate.

- Install the throttle shaft seal with the sealing lip downwardly in the carburetor body until the top of the seal is affluent with the acme of the carburetor. Turn the shaft until the flat side is facing out. Adhere the throttle plate to the shaft with the screws so that the numbers on the throttle plate face the idle mixture spiral and the dimples face in.

- Install the inlet needle seat with the groove down, using a bushing driver. So, install the inlet needle on the float and install the associates in the carburetor body.

- Insert the hinge pivot and center pin. Then, install the rubber gasket on the carburetor and attach the fuel basin, fiber washer and bowl nut.

Footstep vi: Attaching The Carburetor & Air Cleaner Associates

- Position the carburetor and then the beveled edge fits into the fuel intake piping and attach the carburetor with nuts or bolts, as required, leaving these fasteners loose for final tightening with a torque wrench. Consult your Briggs & Stratton Authorized Dealer for proper tightening torque.

- Install the air cleaner assembly, making certain that the tabs on the lesser of the air cleaner are engaged.

More Carburetor Repair Resources

How to Clean a Pocket-size Engine Carburetor

How To Repair A Briggs And Stratton Carburetor,

Source: https://www.briggsandstratton.com/eu/en_gb/support/faqs/browse/carburetor-rebuild.html

Posted by: scottdregat.blogspot.com

0 Response to "How To Repair A Briggs And Stratton Carburetor"

Post a Comment